Press

Shower space in just a few steps: Bielefeld boarding house relies on new installation solution by Bette

The second boarding house of the Stayery brand is to be built in the immediate vicinity of Bielefeld main station, after the Berlin branch commenced operations at the beginning of February 2019. As in the capital, the offer of the 126 serviced apartments in Bielefeld is aimed primarily at young business travellers who want to combine the convenience of a short-term apartment with the service of a hotel. The installation of the shower trays in the Bielefeld building is just as modern as the concept: in order to make the installation faster, cheaper and standard compliant, a new combination solution by Bette is to be used here.

The boarding house on Herforder Straße is six storeys high and consists of two identical complexes. It is operated by BD Apartment GmbH and will be ready for occupancy in the third quarter of 2019. The top floors offer around 1,400 square metres of office space including co-working spaces, and the 22- and 30-square-metre apartments are located on the floors below. Each has a bathroom, bedroom, pantry kitchen and desk, as well as high-speed internet, a smart TV with Miracast and weekly cleaning. There are also community areas for the residents that act as an extended living room.

The architect of the Stayery is Frank Stopfel of Bielefeld, while the Architectural Studio Aisslinger of Berlin is responsible for the modern interior design of the fully furnished apartments. The installation of the building technology was carried out by Friedrich Reitemeier GmbH of Vlotho, who opted for an innovative combined solution by Bette for the shower areas: super-flat shower trays made of glazed titanium steel are used in conjunction with the new Easy Connect installation box and the company's minimum tray carrier.

Significant reduction in effort for installation and sealing

In combination, this ensemble significantly reduces the on-site effort, as the products are largely pre-assembled on delivery, which simplifies installation and reduces the number of work steps. "Bette's installation solution convinced me right away," says Christian Mowe, who oversaw the project on behalf of Reitemeier GmbH. With the conventional installation solutions of any brand and manufacture, he was always irritated by the fact that the assembly was tricky and needed a lot of fine motor skills, and was also not convinced by the seal. "But with Bette's new solution, you can see at first glance that it can be processed and connected cleanly and safely. Which has been confirmed on-site! The seal is now the responsibility of the tiler, and makes life easier for our fitters," says Mowe.

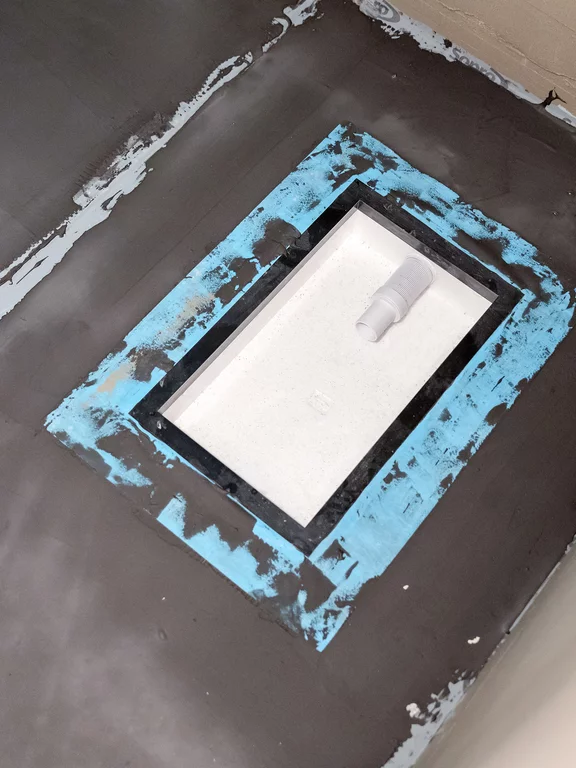

Processing the components was easy: first, the installation box was placed on the floor as a placeholder for the waste or overflow fitting, connected to the sewage pipe and closed with the supplied lid. This was followed by the impact and thermal insulation, after which the screed was applied. Once it was dry, the box was cut to the required height and a pre-assembled sealing cuff tested to ETAG 022 Kiwa fitted.

There was no need for lining to adapt to different height levels, as Easy Connect's installation height can be flexibly selected between 105 and 205 mm. In order to integrate the box into the composite seal to DIN 18534, all that was then required was for the tiler to coat the screed.

Self-cleaning waste for easy cleaning

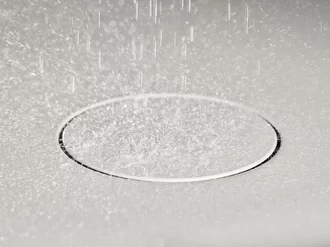

When it came to the shower waste fitting, the Stayery opted for the new self-cleaning BetteSolid. Thanks to its special construction, the intelligent waste technology has no dead corners or burrs on the inside. Hair and dirt can no longer get caught in the drain or pipe segment behind it, and are simply flushed into the sewer system – reducing cleaning time, cleaning agents and maintenance requirements for the hotel.

Connecting the shower waste fitting is easy, as the components are perfectly matched to each other. If required, any other drain set can be connected. Since the pre-installed connection of Easy Connect is flexible and can be extended to the appropriate length – similar to the accordion principle of drinking straws – this is particularly successful because there is always enough room for manoeuvre upwards or to the side.

Installation time almost halved

Use of the minimum tray carrier by Bette also greatly speeded up the of the super-flat shower tray. The tray carrier was pre-assembled to the shower tray at the works and then simply glued to the screed, which is possible with standard commercially available mounting adhesive, non-pressing construction foam or silicone. Thanks to the combination with Easy Connect, the bath edge required no further seal.

"Bette's solution was processed very quickly. I'd guess that we almost halved the amount of time required for the solutions that we have used in the past. With 126 units as in the case of the boarding house, this is an extremely pleasing saving in time," says Mowe.

Important in a hotel: as well as saving time, Bette's practical solution also offers excellent sound insulation. When mounted on screed with insulation, the 17 dB(A) achieved with the combination of super-flat shower tray and minimum tray carrier more than meets the increased requirements of sound insulation level 3 of VDI 4100.

Mowe: "Personally, I appreciate the fact that the screed under the shower tray is now almost continuous. This provides better sound insulation for the rooms below, as there is only a minimal cavity."

Easy-care and strong in daily hotel life

Thanks to the glazed titanium steel, the new shower areas are also perfectly prepared for tough daily life in the boarding house. The high-quality material is not only extremely durable and robust – Bette guarantees it for 30 years – but is also very hygienic and easy to care for with its smooth, resistant surface.

Another benefit is that the Easy Connect installation box means the shower's drain can easily be checked for leaks at any time. Simply unscrewing the shower drain is all it takes for a quick look inside the box.