Our production facilities

Our bathroom products are made exclusively on our own premises in Delbrück

Why? Because this is where we perfectly combine top craftsmanship and engineering skills, careful production and technical sophistication. Made in Germany, in fact.

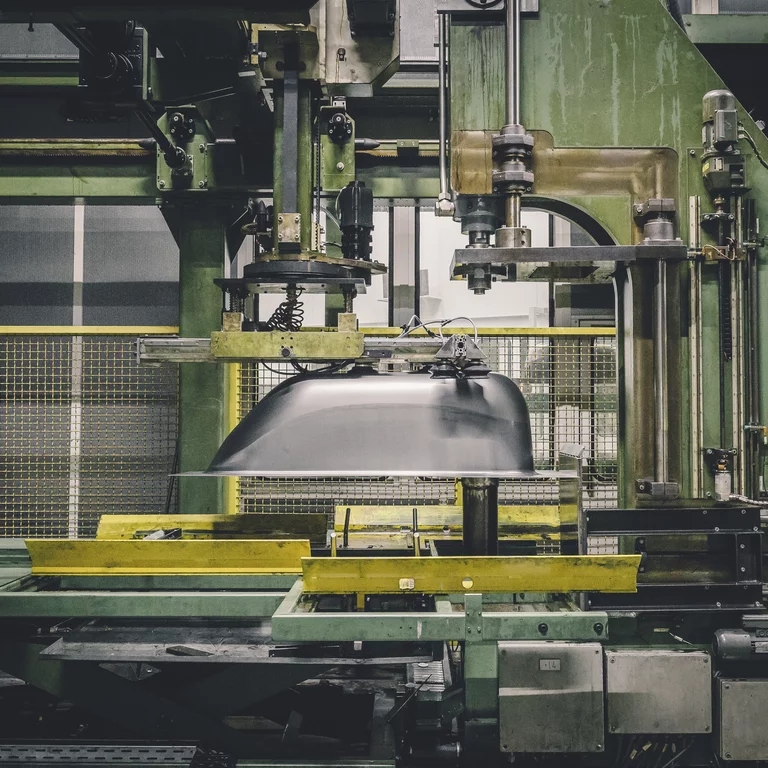

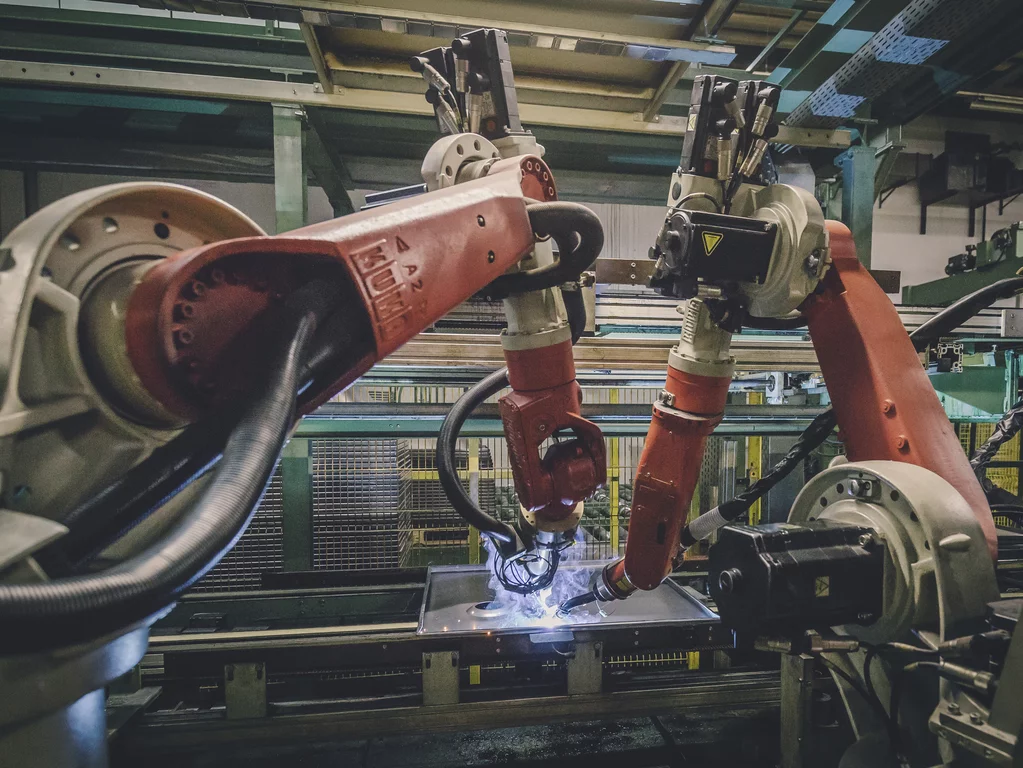

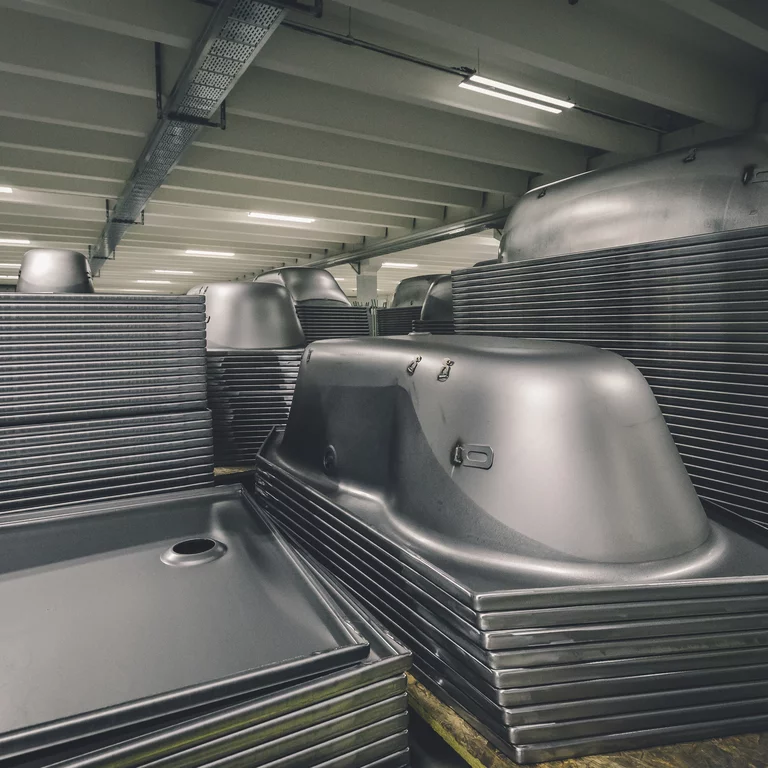

Where man and machine work together intelligently: our works in Delbrück. Around 390 people work here, with some 160 of them manufacturing our exclusive bathroom products in glazed titanium steel. With the help of huge steel presses and articulated robots. A veritable hive of activity, usually in several shifts.

Although many other companies of our size now manufacture their items all over the world, at Bette everything comes from here, from East-Westphalia. This is thanks to the special people here and to the sophisticated production processes that are only available at our works in Delbrück. Bette has been manufacturing bathroom products using its own forming technique since the 1970s. The company simply didn't have the money for an off-the-peg system – for mass-produced goods. So it opted for its own machine concept, universal and flexible, and stands by that choice to this day.

The forming technique to Bette's principles enables it to provide some 35 million different model, size and colour combinations in the shortest possible time. Bette opts for design, for premium – and for baths that are made to measure. The company can also manufacture a single one-off item at any time.

The special deep-drawing process allows the titanium-finished steel sheets to flow into the mould slowly and precisely. The result is a strong almost uniform thickness that saves resources and is highly exclusive.

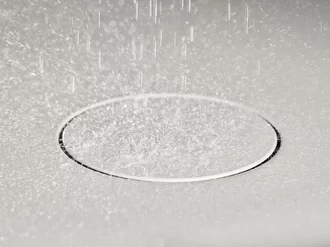

Of course, there also has to be the desire to do better, to question every single product. This, for instance, is how the BetteFloor shower area was created.

The manual work starts in the manufacturing facility and grinding shop.

Anything that cannot be deep-drawn is shaped and sized by hand. Not a job that can be done by just anyone; it takes many years of experience. The welders and grinders work with absolute precision.

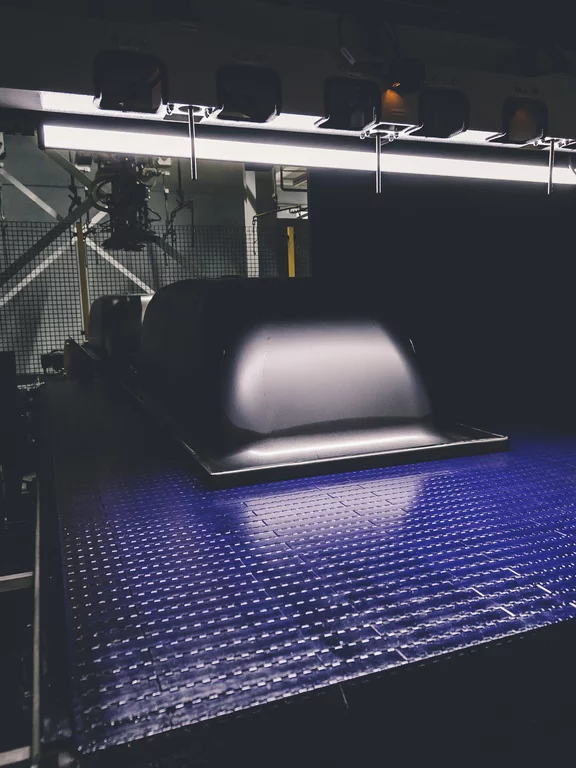

There's a powdery warmth in the enamelling works.

In the robotic ballet, spray nozzles evenly apply the layers of enamel to the bathroom products - in a precisely detailed choreography. The top and colour layers are applied in a wet-in-wet technique after the base glaze.

This production process, which has been perfected over decades, enables us to create spectacular forms that are also exceptionally resilient: Technical sophistication combined with perfect craftsmanship.

Every year there's a new sensation here! A new colour, a great shape, some kind of fantastic model! And then I have to work out how I'm going to get it through the furnace. It's something I always look forward to.

At our works, we also manufacture, by hand, exclusive special models ranging from special size to bathrooms for cruise ships The factory also serves us both as a design lab and as a field for experimenting with new ideas and developments. But above all, it is the loyalty of our staff that gives us the special freedom to think outside the box.