From covers for outlets to overspray: We recycle with passion and good ideas

We use our materials as effectively as possible, but still there is inevitably a certain amount of waste. And there may be the occasional mishap in production from time to time. We are constantly optimising our processes and reducing material consumption. The result? We don't automatically dump faulty products - we'd rather recondition them so they are flawless. Or choose a new path: for instance, the BetteAir outlet cover is a circular product.

What can be done against the exploitation of the earth? I look to see how we can make the processes here in the company more sustainable. After all, it's no good just talking about sustainability; we have to live it as well.

Scrap and waste produced in our works is returned to steel production, thereby closing the circle. But that's not enough to us as a responsible company. We'd rather try to use the materials as effectively as possible in every stage of production.

So what specifically does that mean? For instance, that we recycle the remnants from the steel sheets that we cut the blanks for our bathroom products from. This calls for creativity so that we have important accessories such as bath feet or hanging tabs at the end.

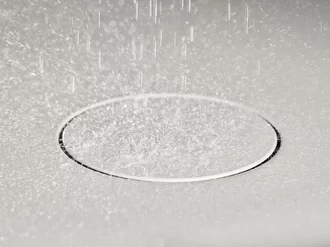

The cover for our new BetteAir shower surface is one of these circular products. And we are proud that almost no waste is generated during the production of BetteAir.

This is because we are constantly reviewing our processes and try to be even more resource-friendly in our production. This also applies to the oil that we use in our deep-drawing process to prevent the steel blanks from cracking as they are being shaped. We collect it and reuse it as a valuable raw material. The same applies to the enamel that mists as it is applied to the blanks - known as overspray. We also collect that and reuse it.

The topic of recycling is becoming increasingly relevant – not least because of the scarcity of raw materials. As a company, we are committed to meeting the legally required CO2 limits. I believe we have a responsibility towards future generations.

Overspray:

We return about 0.55 tonnes of overspray to the enamel production every day.

Offcuts:

We recycle any remnant from a steel sheet that is longer than 300 mm.

Drawing oil:

The oil that we use to ensure that our steel blanks do not crack during the deep-drawing process consists of 5% recycled drawing oil. We collected it during the earlier processes and reuse it.

And of course, things do occasionally go wrong - perhaps the coating on a bath is flawed. The enamel may be uneven after firing. There could be a dent in a shower surface. We don't dump faulty products like these. We recondition them until they are flawless and comply with the high standards of our quality control. And if a product ever is beyond saving, we'll return it to the steel production process.

Are we perfect when it comes to recycling? Probably not, no. But we're working on it - we promise!

Further topics